In Brief

The concept of an agile supply chain has been around for years, but planning and executing flexible supply chains has never been more critical than it is today.

Across industries, supply chains have traditionally been informed by historical data and relationships. Yet, in the unprecedented economic environment created by major disruptions (such as COVID-19), planning for the here and now is hindered by legacy data that often bears no resemblance to the current reality. Even beyond the current pandemic, though, supply chain managers have always sought to make their domains more agile as they struggle to respond in real time to a constant stream of macro conditions that threaten to upend their business models (e.g., weather disasters, geopolitical uncertainty, economic realities, etc.).

Although change is constant in supply chain management, just 21% of respondents to Gartner’s “Weathering the Storm” survey reported that their supply chain networks were “highly resilient” today. To empower today’s agility and tomorrow’s resilience, businesses must cultivate the capabilities required to plan at various levels and on multiple time horizons for a range of possible scenarios. But truly forward-thinking organizations will take it a step beyond mere scenario planning.

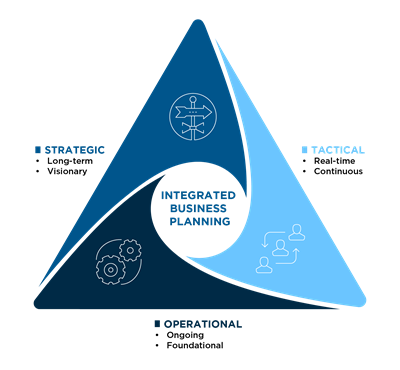

Integrated business planning is achieved by building and connecting enterprise competencies (e.g., technology strategy, data governance, team structures) that enable both real-time responsiveness as well as more strategic longterm visibility of the entire supply chain. The development of this technology-enabled planning continuum — composed of strategic, operational and tactical planning — is the next level of supply chain digital transformation.

Strategic Planning

Align Supply Chain Goals to Organizational Strategy

A clearly articulated strategic plan is the first step toward supply chain success. It informs future financial and product- and service-development decisions that can make or break an organization’s longevity and sustainability. The clear connection of supply chain goals and metrics to the organization’s overarching strategic vision helps business leaders build flexibility into their supply chains without deviating from the core mission.

Especially throughout times of disruption, it can be easy for supply chain managers to get so mired in the day-to-day data churn that they lose sight of the bigger picture. That is when it is important to step back and assess the effectiveness of operational and tactical plans by asking critical questions like:

- What can we learn from that quick decision we had to make?

- Was it the right decision?

- What might we do differently if that issue came up again?

- Did the outcome of that decision support the organization’s mission, vision and/or long-term strategy?

The metrics businesses use for this type of planning provide a zoomed-out, more holistic view of how supply chain adjustments, improvements and enhancements are (or are not) supporting the organization’s strategic direction. Businesses will want to look at their cash-to-cash cycles, market share, efficiency, supplier performance and other strategic key performance indicators that measure the effectiveness of end-to-end processes and overall business outcomes. The key differentiator within this capability lies in leveraging these lessons to improve future strategic plans.

Operational Planning

Proactively Develop Scenario Plans to Support Organizational Agility

Operational planning, one-third of an integrated business planning approach, is the ongoing, foundational evaluation and adjustment of business processes to support agility. It is the connection point between the immediacy of tactical planning and the visionary, future-focused aspects of longterm organizational strategy.

This work, in part, may take the form of scenario or contingency planning for myriad possible future states. Businesses, especially those that are heavily reliant on their supply chain networks, should have several plans in place well before a major disruption occurs. It is this forethought that will enable sustained momentum and agility. Indicators should also be clearly defined to offer guidance on when and how to execute specific plans. Without these markers, even the most robust scenario plan is ineffective.

To maintain their relevance, these plans should be regularly reviewed and refreshed to account for novel market dynamics, impending threats, internal shifts, new competitors, consumer preference shifts and other evolutions.

Tactical Planning

Move From Discrete to Continuous Data Review Cycles to Enable Rapid Responses

Periods of disruption are often characterized by extreme fluctuations in market appetite for particular products or services. In these times of unrest, supply lines may be severed, transportation routes may be cut off or previously fruitful supplier relationships may deteriorate. In addition, as we’ve recently experienced, demand signals may be disrupted. When this happens, the common industry signals or signposts businesses use to forecast logistics, optimize inventory and develop scenario plans may become jumbled, rendering supply chain data difficult to decipher or even unusable for this purpose.

To navigate these headwinds, leaders must be prepared to take intelligent risks and make difficult, real-time decisions using imperfect data. Tactical planning takes this instability into account to leverage data to support quick adjustments to previously created scenario plans. These road maps should not be static documents that are read once and then shelved. Especially during times of disruption, they should be regularly reviewed and amended to meet the demands of the day and allow for rapid course corrections.

The key to unlocking this capability lies in developing the enterprise’s analytical maturity to enable shorter review cycle times and diversification of data sources. This means moving beyond the review of only organizational data to also include syndicated industry data and social media monitoring (among others). In fact, according to the American Productivity & Quality Center (APQC), there is a direct correlation between the use of data to aid real-time decision making and shorter cash-to-cash cycle times. The key question for leaders is: How can we shrink processing times, iterations and feedback loops to take advantage of real-time monitoring and scenario management?

Supply chain leaders should be looking at data on a more regular basis (perhaps even daily) to coursecorrect as internal and external factors change rather than responding reactively to events that transpired days, weeks or even months ago. Many businesses are accustomed to discrete monthly, quarterly or annual reviews, but to maintain supply chain (and organizational) agility, this analysis must become continuous. While all data in periods like these will remain flawed, the tighter the window of measurement, the more accurate the data will be and the more precise scenario planning can become. Given the prevalence of automated forecasting and data analysis — enabled by advanced planning systems (APS), artificial intelligence (AI) and machine learning (ML) — in supply chains today, for most businesses, this increase in cadence will not require a significant increase in resources or labor.

Supply chain leaders must be able to see both the forest and the trees (predictive and prescriptive data) on a continuous basis to make real-time and long-term course corrections for the health of the business. It is the intentional use of operational, tactical and strategic plans that will hand businesses the competitive edge today and post-pandemic.

Yet, by leaning into an integrated business planning approach that supplies leaders with multiple diverse opportunities to leverage data to make decisions, organizations may build their resilience and insulate themselves against future disruptions.

KEY TAKEAWAYS

-

Think differently.

Leverage different types of data at different times to keep shifting, short-term and long-term organizational goals in focus. -

Plan differently.

Ensure that planning is integrated across the organization (rather than siloed and static) to provide a more comprehensive picture of the business’s health. -

Act differently.

Use data (organizational, syndicated, benchmark) to make real-time decisions and take intelligent risks in the face of uncertainty.